-

Products

-

Hydraulic Cylinders

-

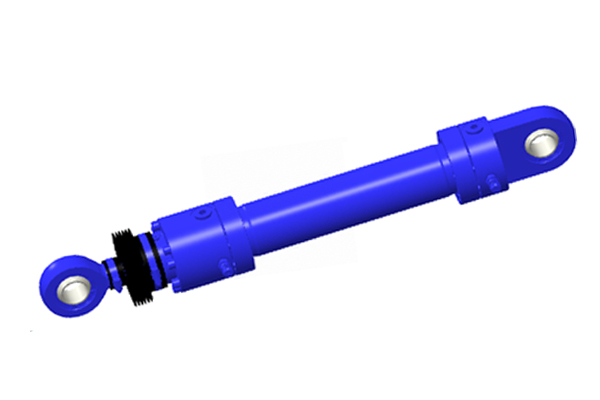

Mobile Machinery Cylinders

-

Industrial Engineering Cylinders

-

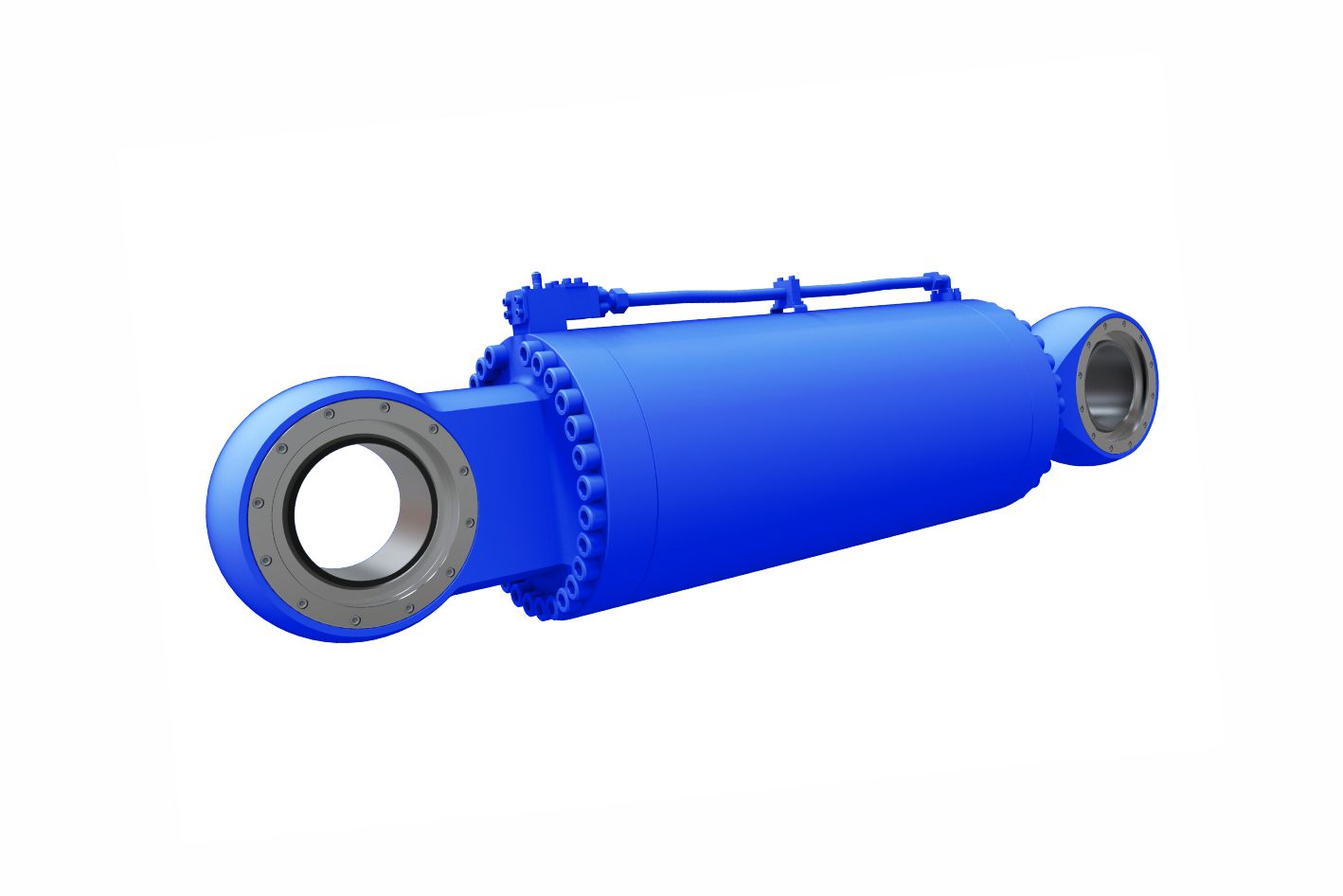

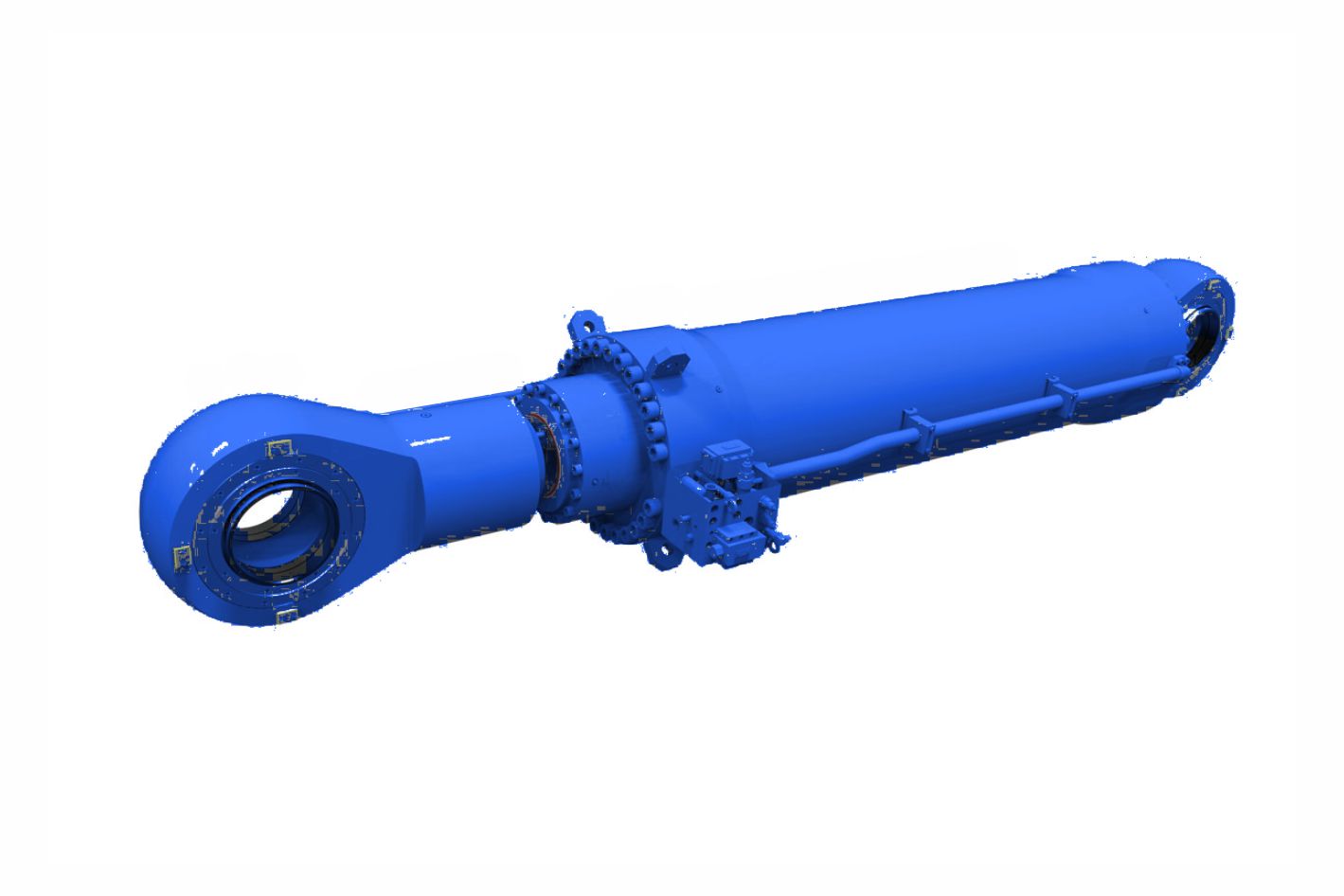

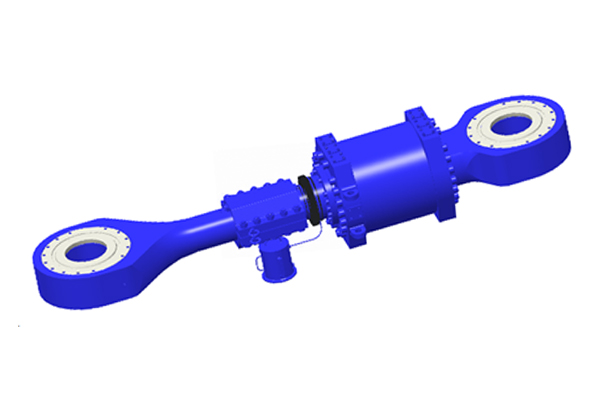

Offshore Cylinders

-

Energy Technology Cylinders

-

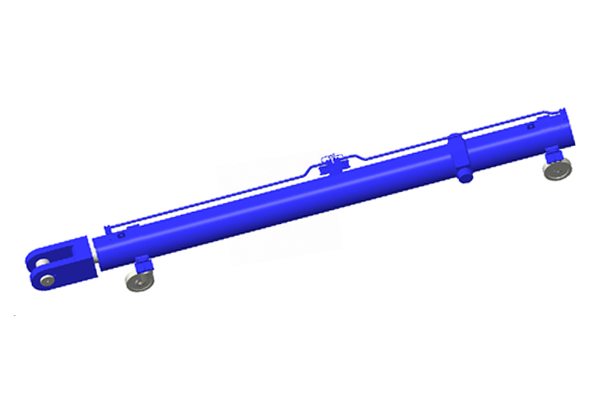

Tunnel Boring Machine Cylinders

-

-

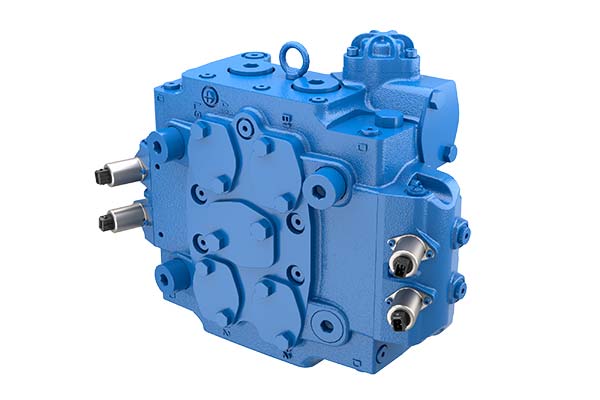

Hydraulic Pumps

-

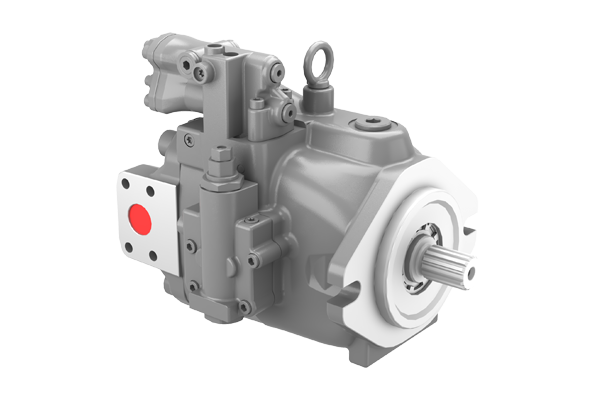

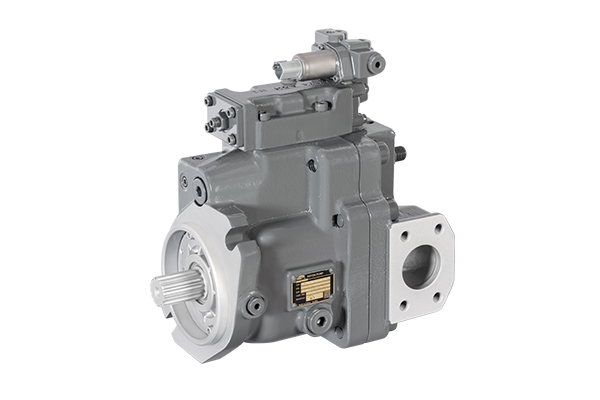

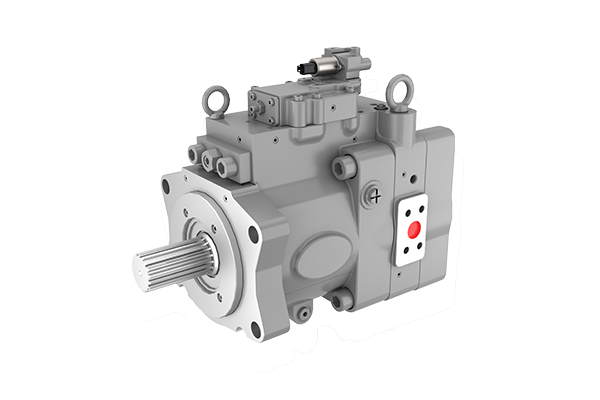

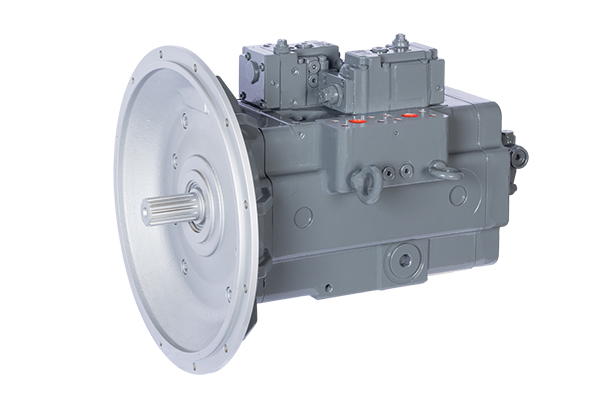

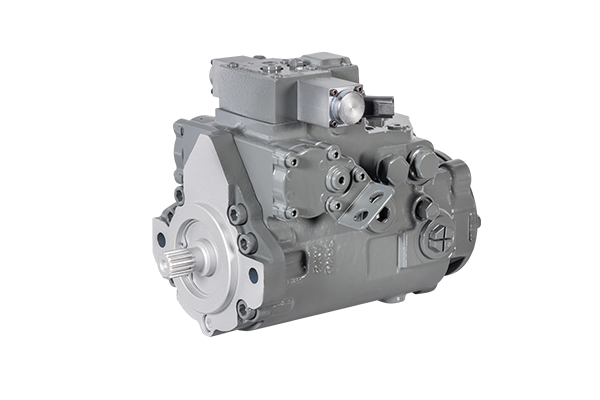

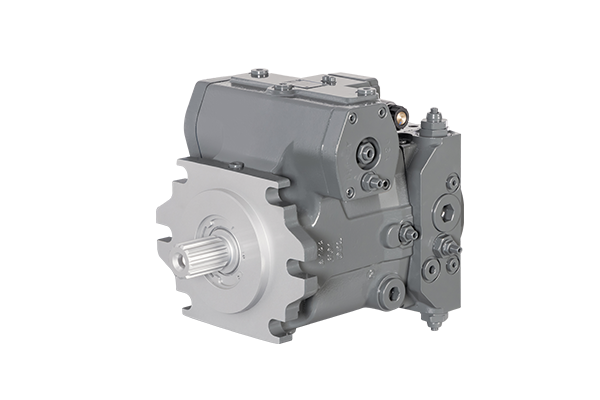

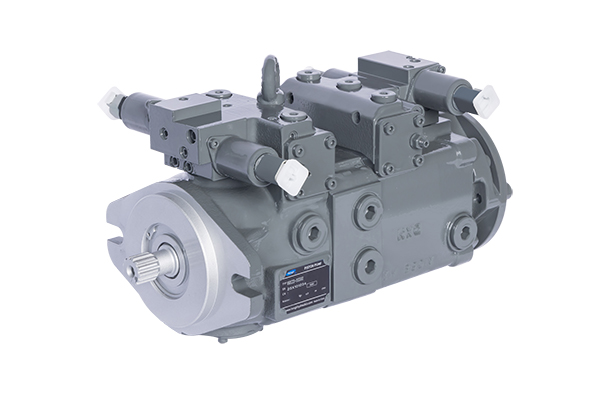

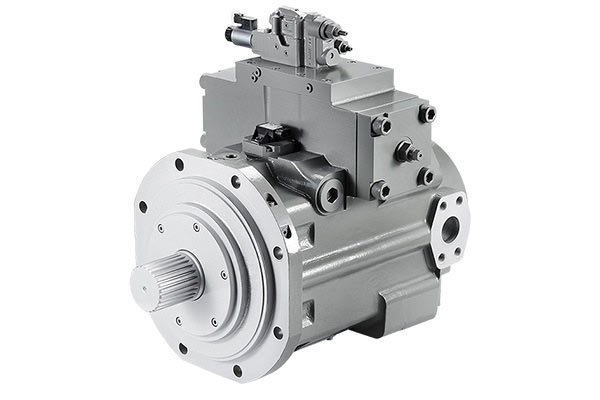

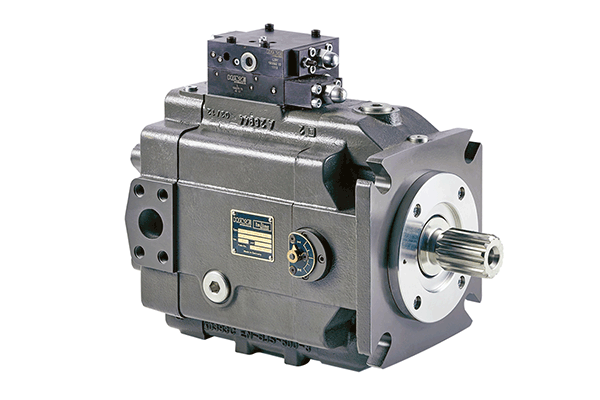

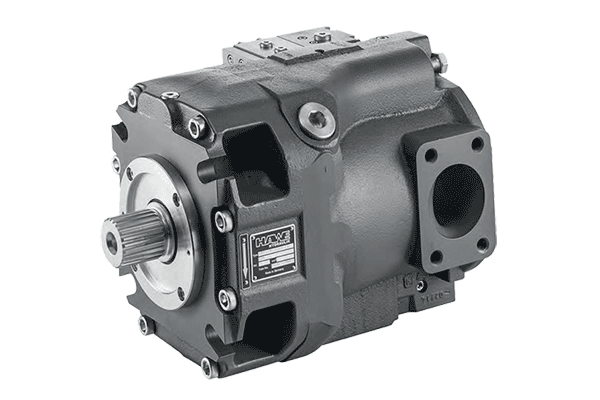

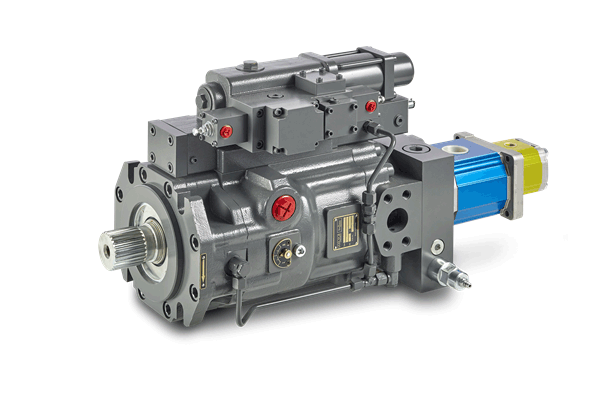

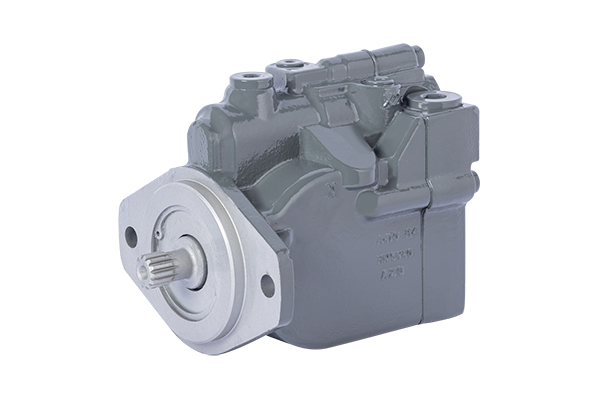

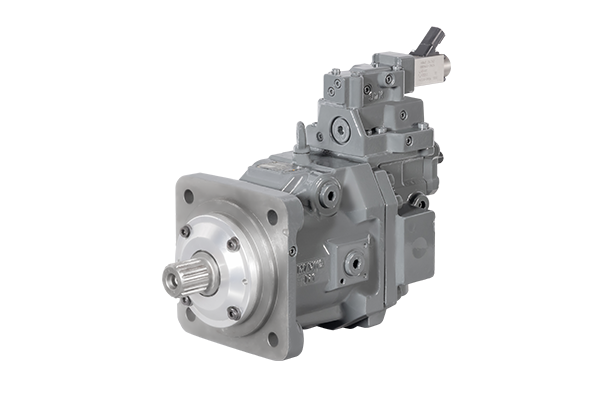

Hengli Piston Pumps

-

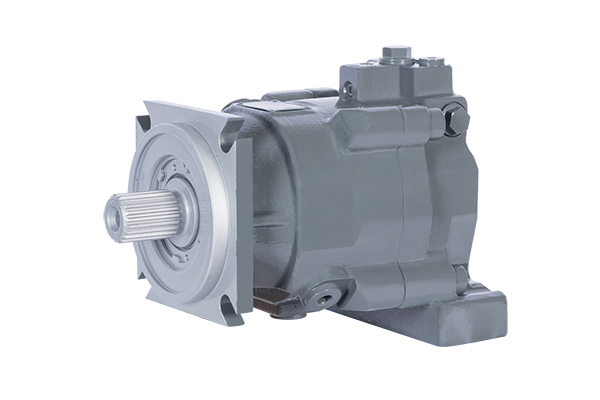

InLine Piston Pumps

-

-

Hydraulic Motors

-

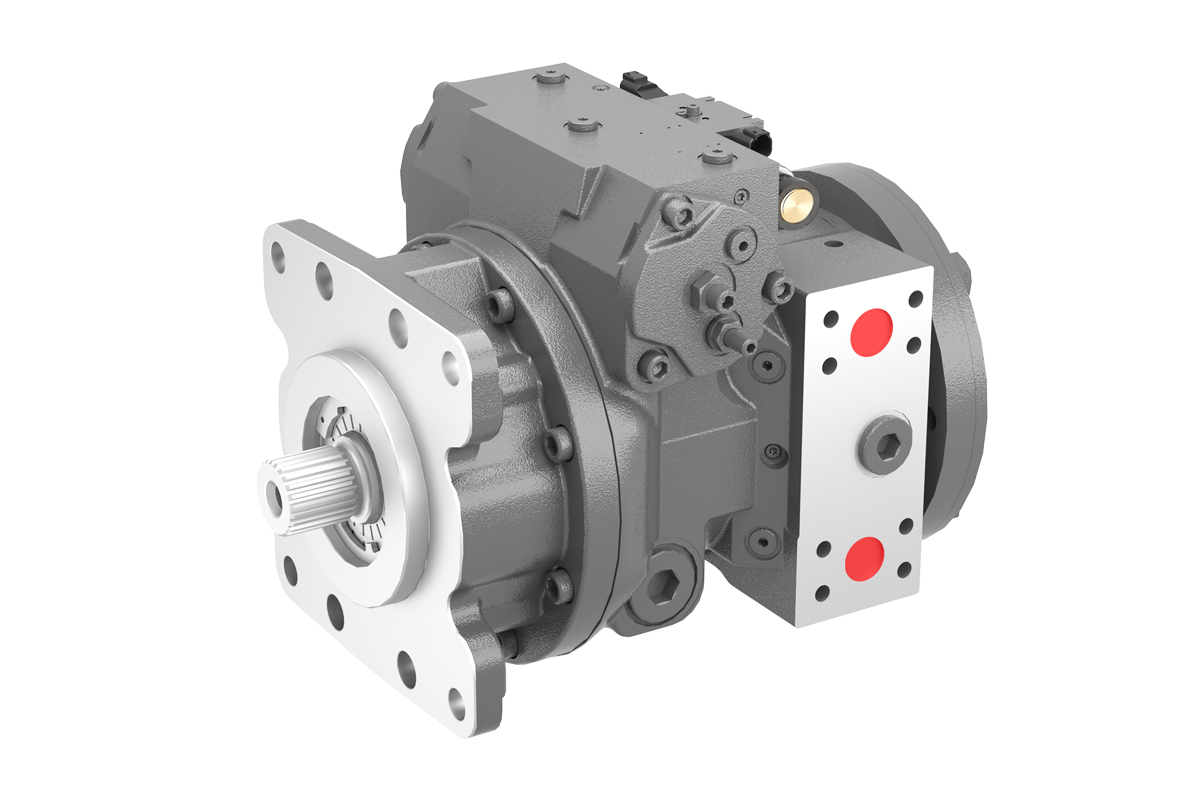

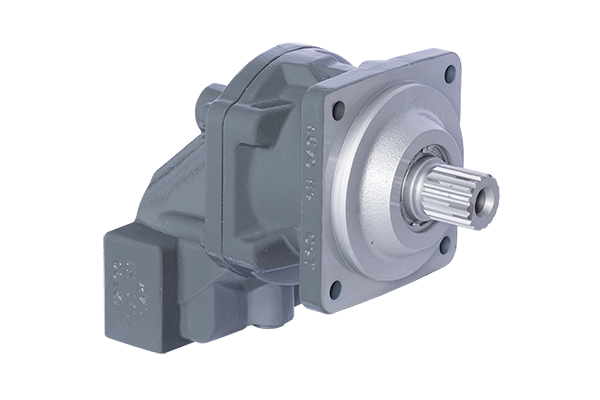

Fixed Displacement Motor

-

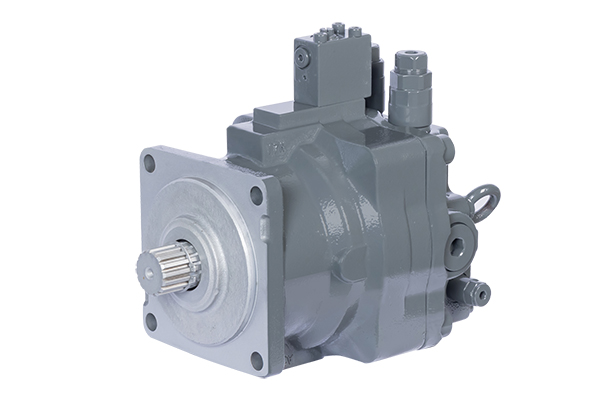

Variable Motor

-

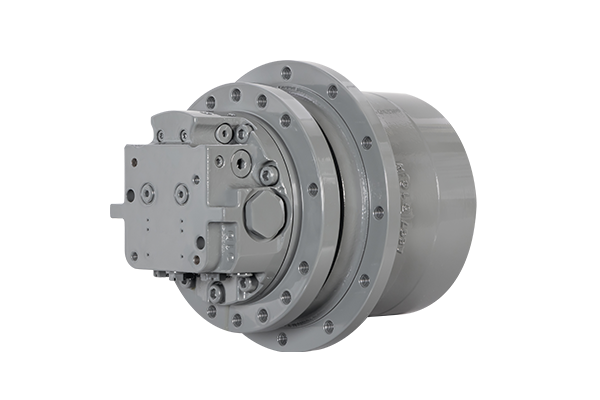

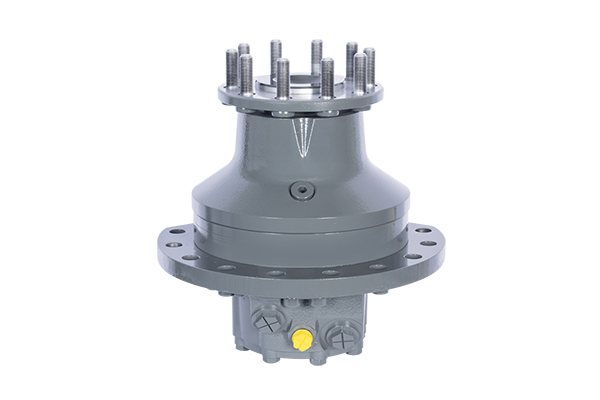

Radial Piston Motor

-

-

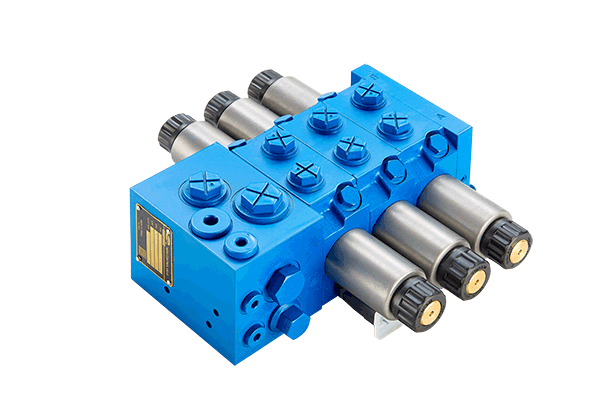

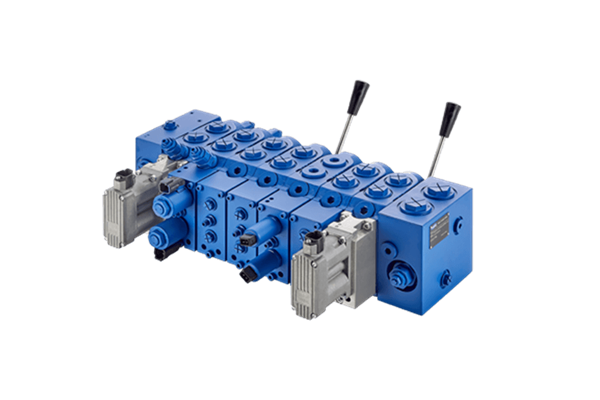

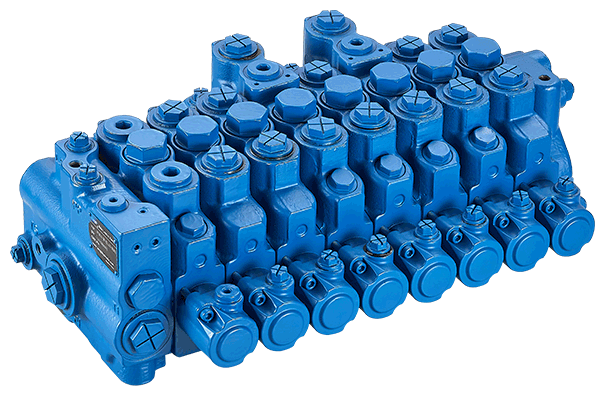

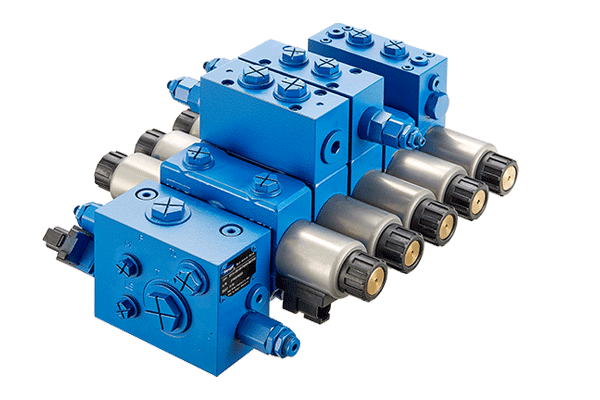

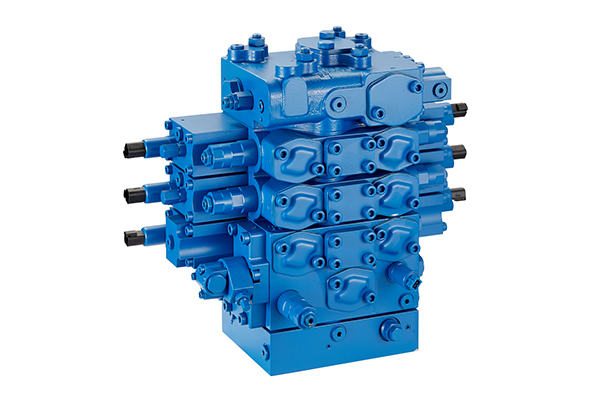

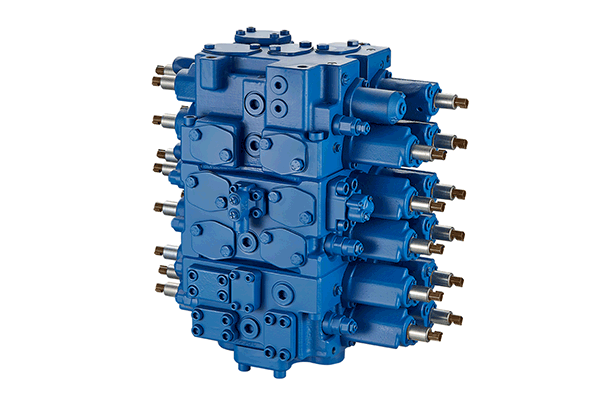

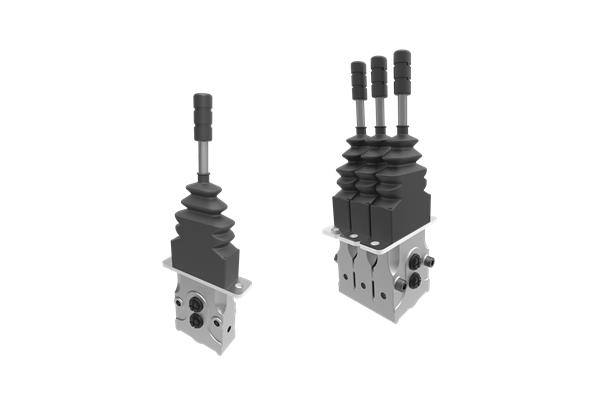

Mobile Control Valves

-

Multi-way Control Valves

-

Pilot Control

-

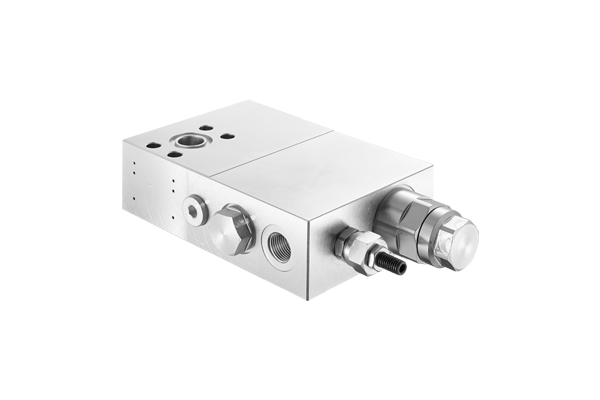

Motion Valve

-

-

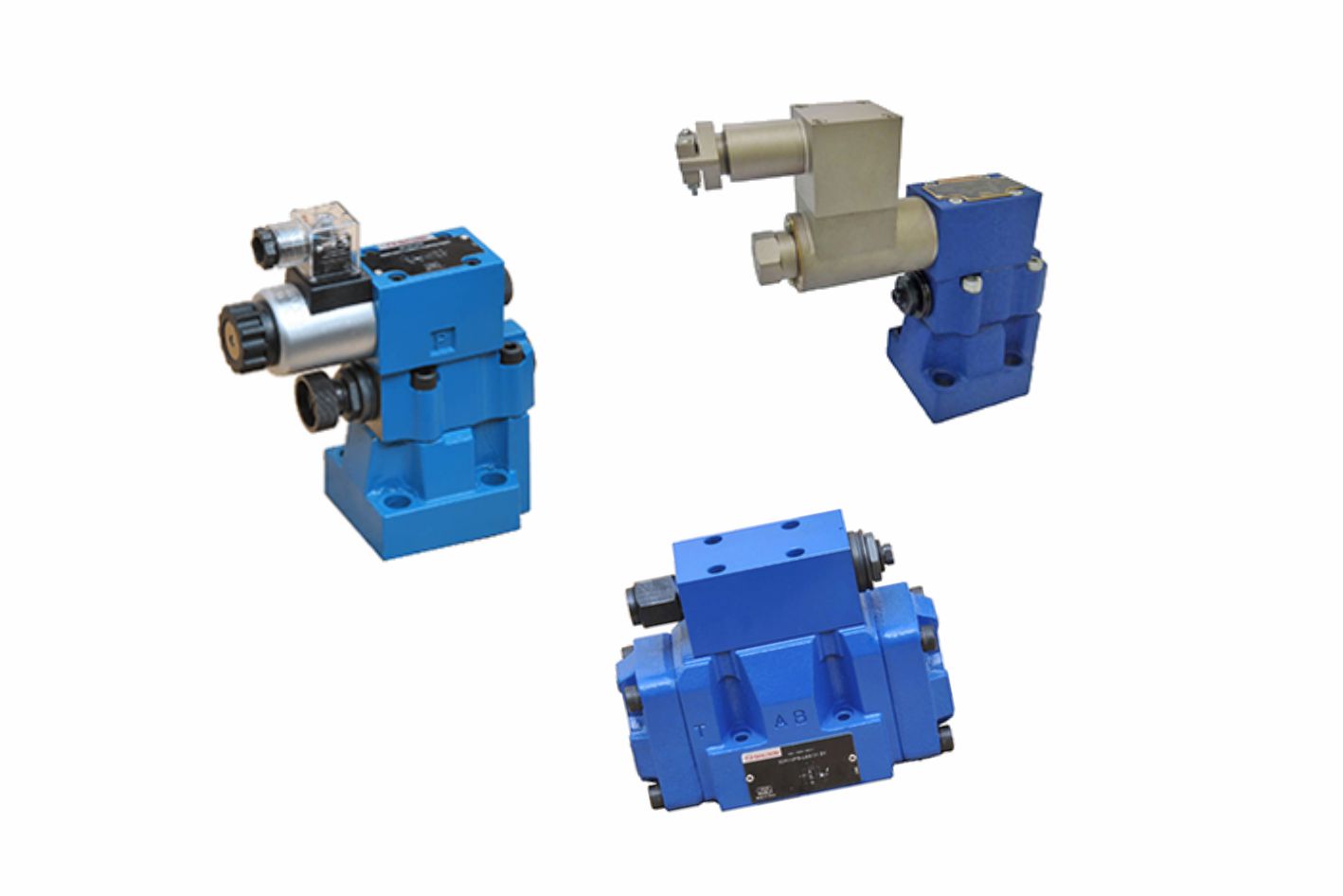

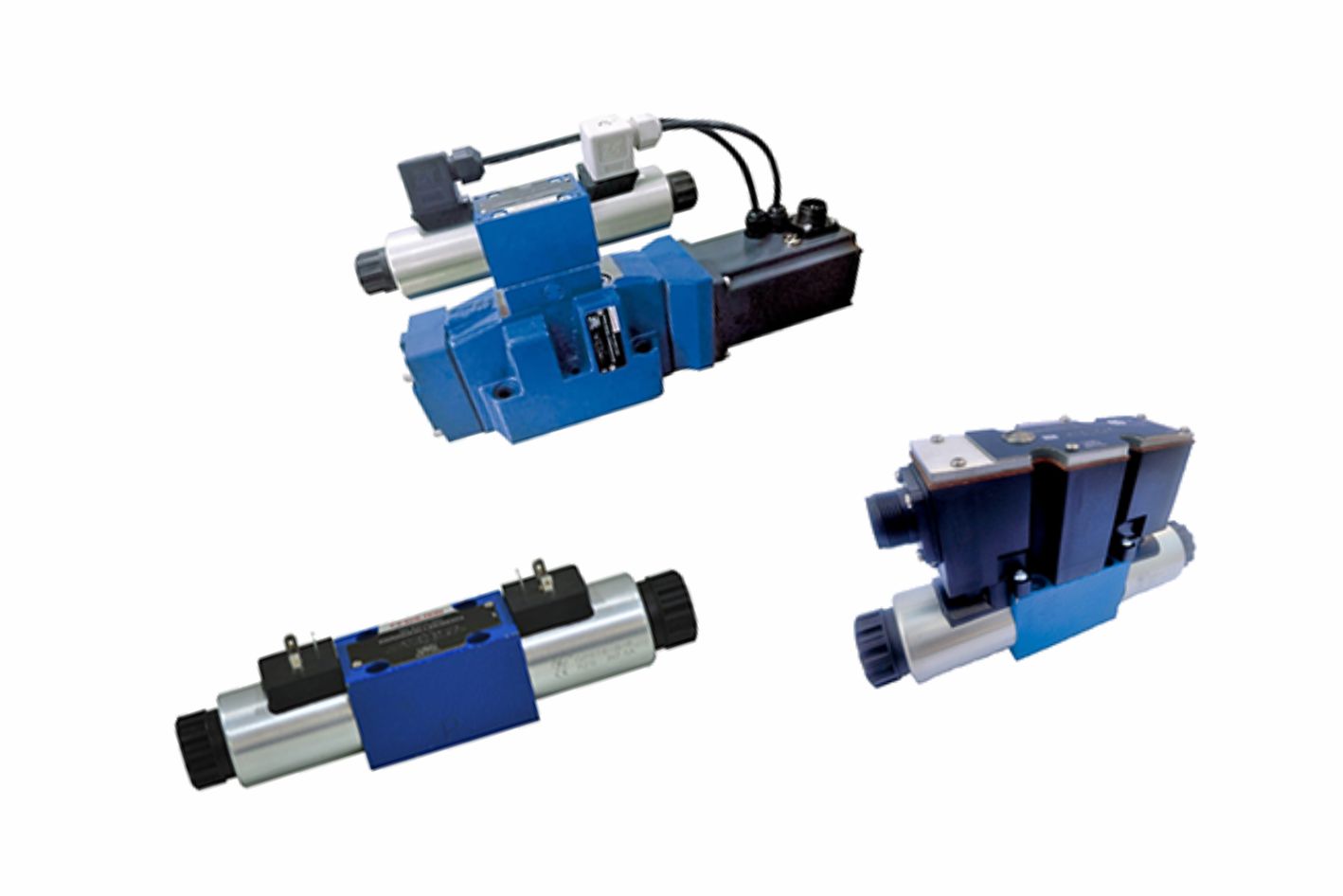

Industrial Hydraulic Valves

-

-

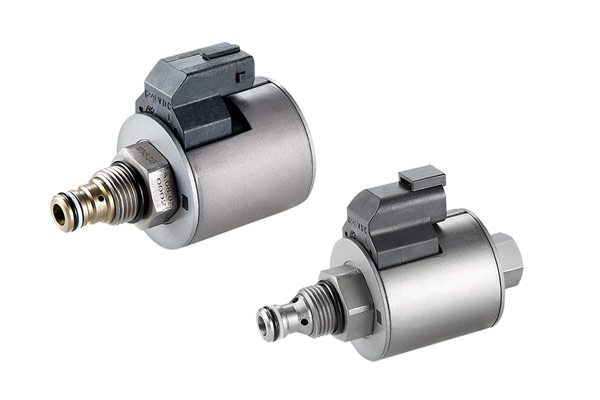

Cartridge Valve

-

-

Orbital Motor

-

HBA

-

HCL

-

HSP

-

HCW/HCG/HCP

-

HSD

-

HRD

-

HBK

-

HCLB

-

HVA

-

-

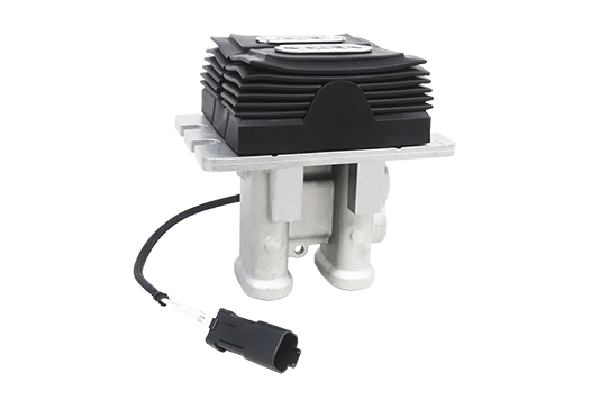

Electronic Control

-

-

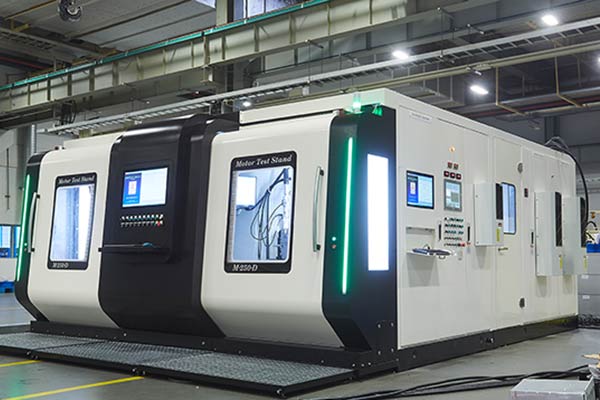

Hydraulic Systems

-

Offshore Hydraulic System

-

Heavy Industry Hydraulic System

-

Test Benches

-

-

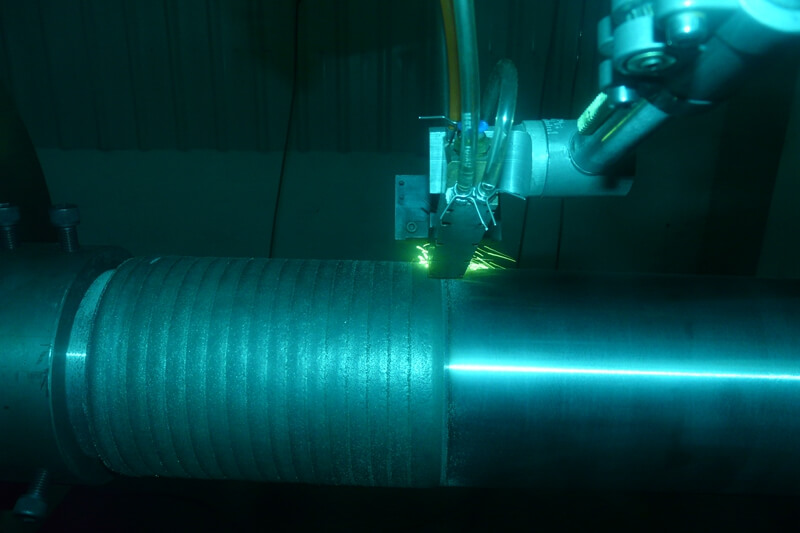

High Precision Cast Iron

-

-

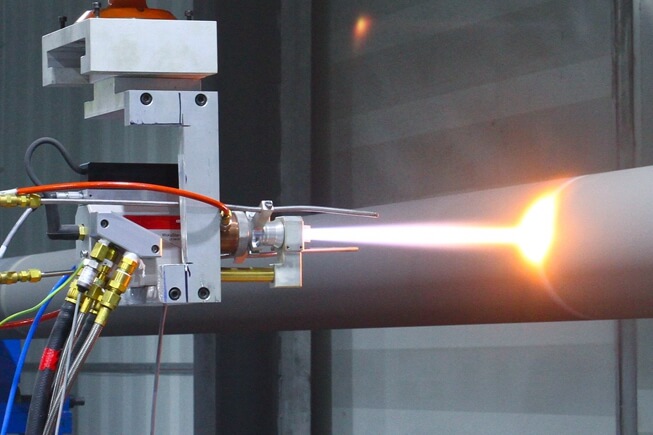

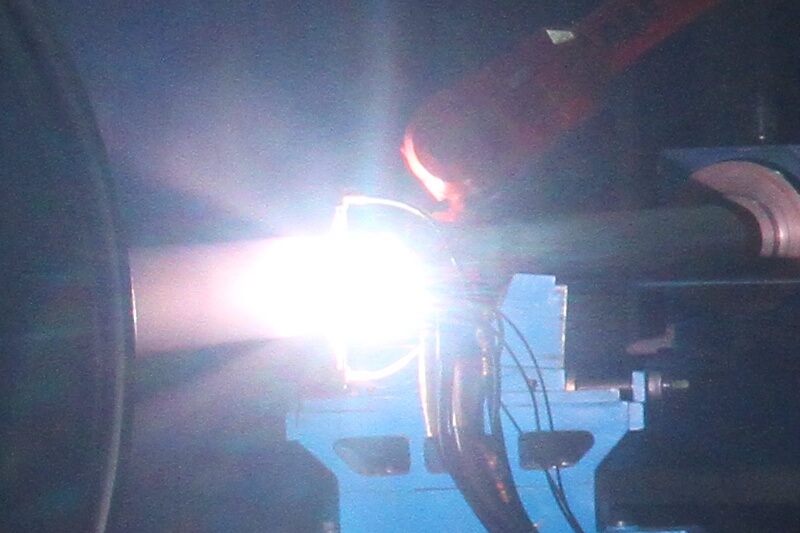

Thermal Spray

-

-

-

Applications

-

Mobile Machinery

-

Construction Machinery

-

Material Handling

-

-

Agricultural Machinery

-

Harvesting machinery

-

-

Industrial Engineering

-

Metallurgical Die Casting

-

-

-

-

-

-

Offshore

-

Marine Engineering Equipment

-

Offshore Platform

-

Port Machinery

-

-

Energy Technology

-

Oil and Gas Extraction

-

New Energ

-

-

Tunnel Boring Machine

-

Tunneling Equipment

-

Tunnel Reinforcement

-

-

-

About Us

-

News

-

Service

-

Global Webs

Directional Valve

Directional Valve  Pressure Valve

Pressure Valve  Flow Valve

Flow Valve  Proportional/Servo Valve

Proportional/Servo Valve  Cartridge Valve

Cartridge Valve  Other

Other  Solenoid On/Off Controls

Solenoid On/Off Controls  Electro-Proportional Valves

Electro-Proportional Valves  Pressure Controls

Pressure Controls  Directional Controls

Directional Controls  Flow Controls

Flow Controls  Logic Valves

Logic Valves

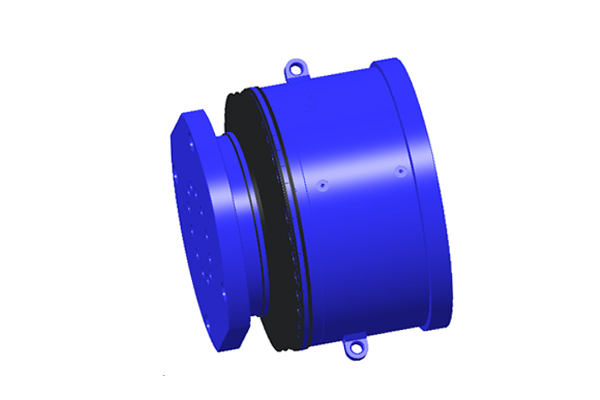

Cylinder Detail

Cylinder Detail

Product Advantages

Product Advantages